Competitive Price for Slurry Pump Spare And Wear Parts - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals

Competitive Price for Slurry Pump Spare And Wear Parts - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals Detail:

Pump Model: SHR/200F (10/8F-AHR)

SHR/200F is equivalent to 10/8F-AHR, a 8” discharge rubber lined slurry pump, which is widely used for corrosive slurry applications. SHR/200F is horizontal centrifugal type heavy duty rubber lined slurry pump. It is used to handle tailings in various mining sectors. Plus, it can also be used to feed cyclones for sand washing plants, quarries, etc. SHR is high corrosion-resistant pump series for the hydraulic conveyance of liquids-solids of any type. It’s wet-end spare parts are made of natural rubber R55, a black soft natural rubber, which has superior erosion resistance to all other materials in fine particle slurry applications. The high erosion resistance of R55 is provided by the combination of its high resilience, high tensile strength and low Shore Hardness.

Applications:

Mine Dewatering; Sand Pumping; Manure Slurry; Oil Sands; Tailings and Aggregate; Coal Production etc.

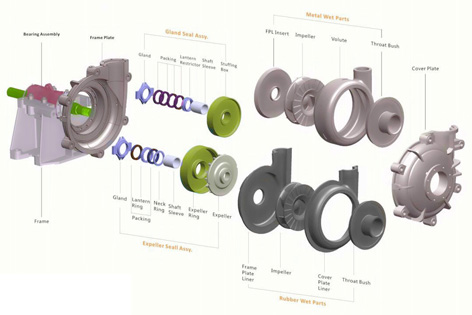

Material Construction:

| Part Description | Standard | Alternative |

| Impeller | R55 | Polyurethane |

| Cover Plate Liner |

R55 | Polyurethane |

| Frame Plate Liner |

R55 | Polyurethane |

| Throatbush | R55 | Polyurethane |

| Split Outter Casings | Grey Iron | Ductile Iron |

| Shaft | Carbon Steel | SS304, SS316 |

| Shaft Sleeve | SS304 | SS316, Ceramic, Tungstan Carbide |

| Shaft Seal | Expeller Seal | Gland Packing, Mechanical Seal |

| Bearings | ZWZ, HRB | SKF, Timken, NSK etc. |

Construction & Structure:

Specifications:

Flowrate: 540-1188m3/hr; Head: 12-50m; Speed: 400-750rpm; Bearing Assembly: FAM005M

(Optional Bearing Assembly: SH005M with Max. Motor Power of 560Kw)

Impeller: 5-Vane Closed Type with Vane Diameter: 686mm; Max. Passage Size: 76mm; Max. Efficiency: 75%

Product detail pictures:

Related Product Guide:

Slurry Pump Knowledge

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Competitive Price for Slurry Pump Spare And Wear Parts - Horizontal Rubber Lined Slurry Pump SHR/200F – Minerals , The product will supply to all over the world, such as: Slovak Republic , Armenia , Doha , Our solutions have national accreditation standards for experienced, premium quality goods, affordable value, was welcomed by people around the globe. Our products will continue to increase in the order and look forward to cooperation with you, Truly must any of people goods be of interest to you, make sure you letus know. We're likely to be delighted to give you a quotation up on receipt of one's in depth specs.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.