OEM Supply China Slurry Duty Pump Replace Horizontal Pump Single Stage Single Suction Pump for Leaching Process

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for OEM Supply China Slurry Duty Pump Replace Horizontal Pump Single Stage Single Suction Pump for Leaching Process, We will wholeheartedly welcome all purchasers within the industry each at your house and abroad to cooperate hand in hand, and develop a vibrant upcoming with each other.

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for Centrifugal Pump, China Slurry Pump, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We’ve been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you’ll be able to come to our factory to find out it. We’ll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we’ll share the top trading practical experience with all our merchants.

Pump Model: SHR/100D (6/4D-AHR)

SHR/100D is equivalent to 6/4D-AHR, a 4” discharge rubber lined slurry pump, which is widely used for corrosive slurry applications. SHR/100D is the most popular pump model among our horizontal centrifugal type heavy duty rubber lined slurry pumps. It is used to handle tailings in various mining sectors. Plus, it can also be used to feed cyclones for sand washing plants, quarries, etc. SHR is high corrosion-resistant pump series for the hydraulic conveyance of liquids-solids of any type. It’s wet-end spare parts are made of natural rubber R55, a black soft natural rubber, which has superior erosion resistance to all other materials in fine particle slurry applications. The high erosion resistance of R55 is provided by the combination of its high resilience, high tensile strength and low Shore Hardness.

Rubber pumps can also be used for applications where metal pumps are widely used, when the pH is 5-8. But they are more often used to handle fine articles with small solids.

Applications:

Mine Dewatering; Sand Pumping; Manure Slurry; Oil Sands; Tailings and Aggregate; Coal Production etc.

Material Construction:

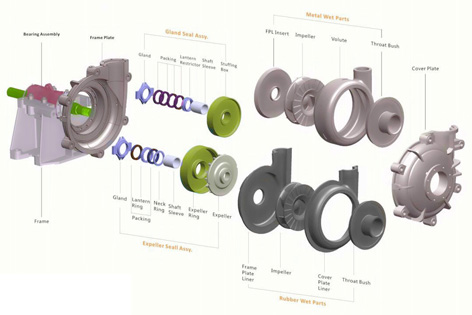

| Part Description | Standard | Alternative |

| Impeller | R55 | Polyurethane |

| Cover Plate Liner |

R55 | Polyurethane |

| Frame Plate Liner |

R55 | Polyurethane |

| Throatbush | R55 | Polyurethane |

| Split Outter Casings | Grey Iron | Ductile Iron |

| Shaft | Carbon Steel | SS304, SS316 |

| Shaft Sleeve | SS304 | SS316, Ceramic, Tungstan Carbide |

| Shaft Seal | Expeller Seal | Gland Packing, Mechanical Seal |

| Bearings | ZWZ, HRB | SKF, Timken, NSK etc. |

Construction & Structure:

Specifications:

Flowrate: 144-324m3/hr; Head: 12-45m; Speed: 800-1350rpm; Bearing Assembly: DAM005M

(Optional Bearing Assembly: DDAM005M, E005M, EE005M)

Impeller: 5-Vane Closed Type with Vane Diameter: 365mm; Max. Passage Size: 44mm; Max. Efficiency: 64%