OEM/ODM Manufacturer China Centrifugal Slurry Pump

Adhering towards the theory of “quality, support, efficiency and growth”, we’ve attained trusts and praises from domestic and international client for OEM/ODM Manufacturer China Centrifugal Slurry Pump, To offer prospects with great equipment and solutions, and frequently develop new machine is our company’s business objectives. We glance ahead for your cooperation.

Adhering towards the theory of “quality, support, efficiency and growth”, we’ve attained trusts and praises from domestic and international client for China Slurry Pump, Sewage Pump, We solution have passed through the national skilled certification and been well received in our key industry. Our professional engineering team will often be ready to serve you for consultation and feedback. We’ve been able to also supply you with no cost samples to meet your needs. Best efforts is going to be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, remember to speak to us by sending us emails or get in touch with us right away. As a way to know our solutions and enterprise. lot more, you’ll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should truly feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

Pump Model: SH/100D (6/4D-AH)

SH/100D is equivalent to 6/4D-AH, a 4” discharge slurry pump, which is also our best seller among our SH series Heavy Duty slurry pumps. SH series slurry pumps are specially desighed for highly abrasive slurries. The wet-end spare parts are available in materials high chrome alloy, or soft natural rubber or polyurethane. The shaft seals are available from gland packing seal, expeller seal and mechanical seal. The SME SH series heavy duty horizontal slurry pumps offer a wide range of world class hard metal and rubber lined slurry pumps for abrasive pumping applications.

Material Construction:

| Part Description | Standard | Alternative |

| Impeller | A05 | A33, A49 |

| Volute Liner | A05 | A33, A49 |

| Front Liner | A05 | A33, A49 |

| Back Liner | A05 | A33, A49 |

| Split Outter Casings | Grey Iron | Ductile Iron |

| Shaft | Carbon Steel | SS304, SS316 |

| Shaft Sleeve | SS304 | SS316, Ceramic, Tungstan Carbide |

| Shaft Seal | Expeller Seal | Gland Packing, Mechanical Seal |

| Bearings | ZWZ, HRB | SKF, Timken, NSK etc. |

Applications:

Lime Slurry; Pulp and Paper; Alumina; Fertilizer; In-Plant Slurry Transfer etc.

Specifications:

| Pump Model | OEM Model | Base Type | Bearing Assembly | Power (Kw) | Flow(m3/h) | Head(m) | Speed(rpm) | Max.Effi. |

| SH/100D | 6/4D-AH | D | DAM005M | 60 |

162-360 |

12-56 |

800-1550 |

65% |

| SH/100DD | 6/4DD-AH | DD | DDAM005M | 110 | ||||

| SH/100E | 6/4E-AH | E | E005M | 120 | ||||

| SH/100EE | 6/4EE-AH | EE | EE005M | 225 |

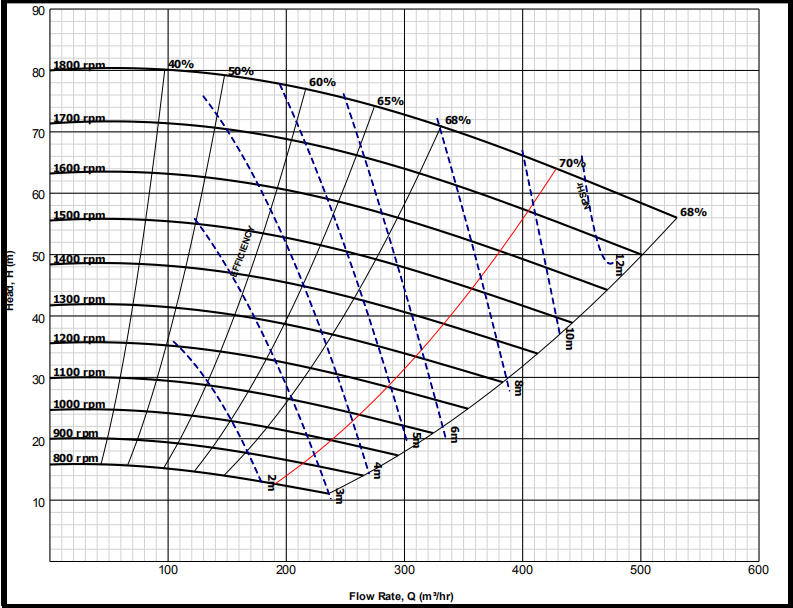

Performance Curve with Standard Impeller, Metal 5-Vane E4147A05:

11