Metal dijejeran nangtung Slurry pompa SV / 40P

Modél pompa lumpur: SV/40P (40PV/SP)

The SV beurat-tugas pompa cantilever sump dirancang pikeun aplikasi merlukeun reliabiliti gede tur durability ti pompa prosés nangtung konvensional tiasa nawiskeun. Desain cantilever beurat-tugas ngajadikeun pompa bah SV idéal cocog pikeun penanganan kontinyu beurat cairan abrasive sarta slurries bari submerged dina sumps atawa liang . The SV beurat-tugas pompa sump terjal nu sadia dina rupa-rupa ukuran populér pikeun nyocogkeun paling aplikasi ngompa. Rébuan pompa ieu ngabuktikeun réliabilitas sareng efisiensi di sakuliah dunya dina Pangolahan Mineral, Persiapan Batubara, Pangolahan Kimia, Penanganan Efluen, Keusik sareng Gravel, sareng ampir unggal tank, pit, atanapi kaayaan penanganan slurry liang-di-tanah.

Konstruksi bahan:

| Katerangan | Bahan baku | Bahan Pilihan |

| Impeller | A05 | A33, A49 |

| Casing | A05 | A33, A49 |

| Balik Liner | A05 | A33, A49 |

| Aci | Baja Karbon | SUS304, SUS316(L) |

| Pipa Discharge | 20 # Hampang Steel | SUS304, SUS316(L) |

| Kolom | 20 # Hampang Steel | SUS304, SUS316(L) |

spésifikasi:

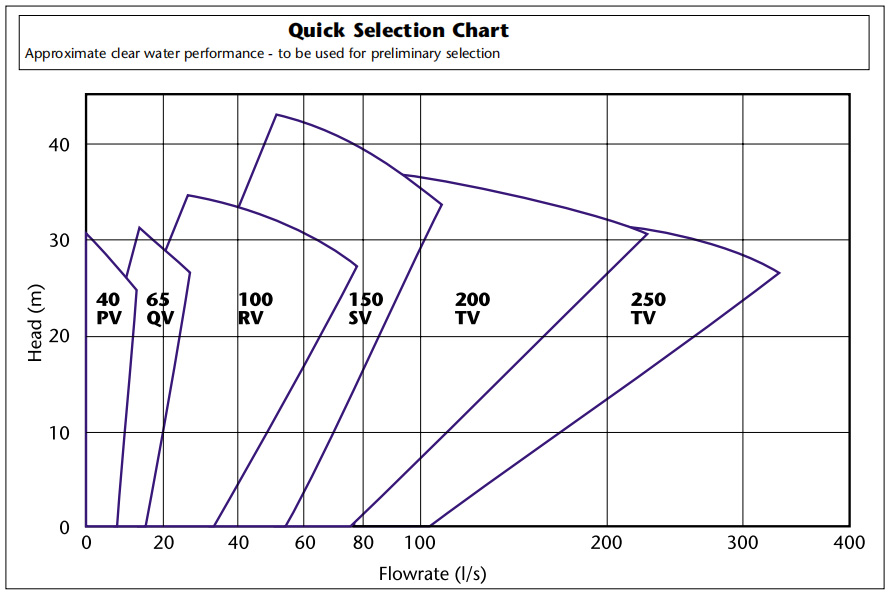

| Pompa | Diijinkeun | Bahan | Performance Cai Herang | Impeller | |||||

| Kapasitas Q | Sirah | Laju | Max.Eff. | Panjangna | No. tina | Vane Dia. | |||

| Impeller | m3/h | ||||||||

| SV/40P | 15 | logam | 19.44-43.2 | 4.5-28.5 | 1000-2200 | 40 | 900 | 5 | 195 |

| SV/65Q | 30 | 23.4-111 | 5-29.5 | 700-1500 | 50 | 1200 | 290 | ||

| SV / 100R | 75 | 54-289 | 5-35 | 500-1200 | 56 | 1500 | 390 | ||

| SV / 150S | 110 | 108-479.16 | 8.5-40 | 500-1000 | 52 | 1800 | 480 | ||

| SV / 200S | 110 | 189-891 | 6.5-37 | 400-850 | 64 | 2100 | 550 | ||

| SV / 250T | 200 | 180-1080 | 10-35 | 400-750 | 60 | 2400 | 605 | ||

| SV / 300T | 200 | 180-1440 | 5-30 | 350-700 | 62.1 | 2400 | 610 | ||